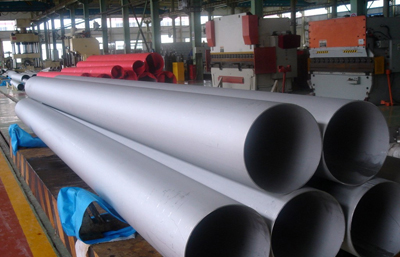

A213 T9 Seamless Round Tubes Alloy Steel

|

Grade |

UNS |

C, % |

Mn, % |

P, % |

S, % |

Si, % |

Cr, % |

Mo, % |

|

T9 |

K90941 |

0.15 max |

0.30-0.60 |

0.025 max |

0.025 max |

0.25-1.00 |

8.0-10.0 |

0.90-1.10 |

Mechanical properties

|

Tensile Strength , MPa |

Yield Strength, MPa |

Elongation, % |

Hardness, HB |

|

415 min |

205 min |

30 min |

179 max |

A213 T9 Seamless Round Tubes Tolerance:

|

Outside Diameter |

OD Tolerance |

WT Tolerance |

Ovality Tolerance |

Cut Length Tolerance |

|

OD≤ 12, 7 mm |

± 0, 13 mm |

± 15 % |

– |

+ 3, 18 mm, – 0 mm |

|

12, 7 mm < OD ≤ 38, 1 mm |

± 0, 13 mm |

± 10 % |

max, 1, 65 mm |

+ 3, 18 mm, – 0 mm |

|

38, 1 mm < OD ≤ 88, 9 mm |

± 0, 25 mm |

± 10 % |

max, 2, 41 mm |

+ 4, 76 mm, – 0 mm |