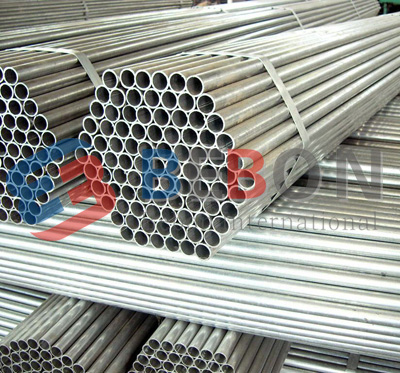

Austenitic Stainless Steels 304 Tube

304 SS is a low carbon (0.08% max) version of basic 18-8 also known as 302. Type 302 has 18% chromium and 8% nickel. Type 304 has slightly lower strength than 302 due to its lower carbon content. Type 304 finds extensive use in welding applications because the low carbon permits some exposure in the carbide precipitation range of 800°F - 1500°F without the need for post-annealing operations.

These austenitic stainless steels are the most versatile and widely used stainless steels. They exhibit excellent corrosion resistance to a wide range of corrosive environments. Type 304 and 304L grades of stainless steel pipe exhibit good machinability and have excellent weld-ability characteristics with or without the addition of filler metals.

304 Stainless steel tube is ideal for all structural applications where greater strength and superior corrosion resistance is required. Having a durable mill finish and an interior welded seam, Stainless steel pipe is widely used for all types of fabrication projects that are exposed to the elements - chemical, acidic, fresh water, and salt water environments. Some sizes are available with a 180 grit brushed polish.

Austenitic stainless steel 304 tube is a cost-effective tube used for both structural and pressure applications. It is available as seamless, for pressure applications, and welded, for structural applications. 304 alloys exhibit high corrosion resistance, high strength, high temperature resistance and high workability. In addition, they are easy to sanitize and sterilize. Higher carbon levels in 304L decrease the weldability of the alloy.

Welcome to inquiry.

Email: [email protected]