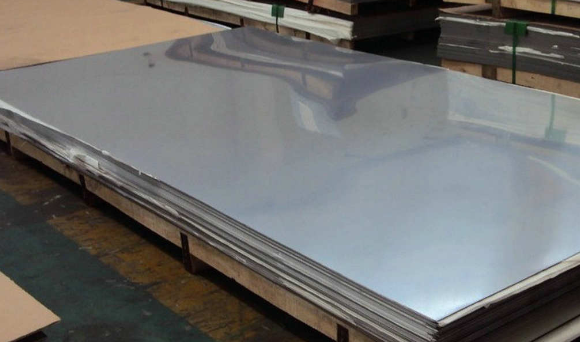

AISI 904L Grade Stainless Steel BA Plate

AISI 904L grade stainless steel BA plate is widely used in the chemical, pharmaceutical, oil and gas industries. AISI 904L grade stainless steel BA plate, coil, sheet is a fully austenic low-carbon variety of stainless steel with additives of molybdenum and copper. Its highnickel and chromium content make AISI 904L grade stainless steel corrosion resistant in both oxidizing and reducing environments. The copper and molybdenum help to make 904L alloy resistant to pitting as well as crevice corrosion. The nickel content makes it resistant to chloride SCC and the low proportion of carbon makes 904L grade alloy resistant to intergranular corrosion. AISI 904L grade stainless steel BA plate is considered especially well-suited to handling sulfuric acid and phosphoric acid, though at high temperatures it may be subject to stress corrosion cracking. Below is the detail of AISI 904L grade stainless steel BA plate chemical composition.

Chemistry(by weight):

Carbon: 0.02% max.

Chromium: 19.00-23.00%

Manganese: 2.00% max.

Nickel: 23.00-28.00%

Silicon: 1.00% max.

Molybdenum: 4.00-5.00%

Phosphorous: 0.045% max.

Copper: 1.00-2.00%

Sulphur: 0.035% max.

AISI 904L grade stainless steel BA plate/sheet typical applications include tanks, valves, heat exchangers, flanges and manifolds. The addition of copper to the composition of 904L aids its suitability for components such as tanks and other products used in handling sulphuric and phosphoric acid.

AISI 904L grade stainless steel can be welded using common fusion and resistance methods. A more highly alloyed filler is recommended to give the optimum corrosion properties in the weld. We recommend you contact your welding consumables supplier who should provide you full assistance and information on welding AISI 904L stainless steel.

If you are looking for AISI 904L grade stainless steel BA plate, AISI 904L grade stainless steel BA sheet or AISI 904L grade stainless steel coil, please contact with our Sales. We will reply you soon.