Advantages of SUS 347 stainless steel

High temperature resistance: SUS 347 stainless steel performs well in high temperature environments and can resist high temperature corrosion and oxidation in t

High temperature resistance:

SUS 347 stainless steel performs well in high temperature environments and can resist high temperature corrosion and oxidation in the temperature range of 400~900℃, especially suitable for pipes with working temperatures below 850℃.

Its good high temperature heat resistance enables it to be used stably for a long time in high temperature environments.

Anti-oxidation performance:

SUS 347 can form a dense oxide film at high temperatures, effectively preventing oxidation reactions and improving corrosion resistance.

In air below 800℃, SUS 347 has good anti-oxidation properties.

Corrosion resistance:

SUS 347 has good corrosion resistance in acids, alkalis, and salt solutions, and its corrosion resistance is comparable to that of SUS304.

In certain specific environments (such as the chromium carbide precipitation range of 800°F to 1500°F), its corrosion resistance is better than that of alloy 321 stainless steel plate.

The alloy can also be used in nitric acid solutions at moderate temperatures, most dilute organic acids, and in pure phosphoric acid at lower temperatures.

Low thermal expansion coefficient and dimensional stability:

SUS 347 has a low thermal expansion coefficient and can maintain good dimensional stability in high temperature environments.

Welding performance:

SUS 347 stainless steel has good welding performance and can be processed and connected by conventional welding methods.

Heat treatment performance:

SUS 347 has good heat treatment performance, and its mechanical properties and corrosion resistance can be improved by heat treatment.

Mechanical properties:

SUS 347 has a tensile strength σb (MPa) ≥ 520, a conditional yield strength σ0.2 (MPa) ≥ 205, an elongation δ5 (%) ≥ 40, a cross-sectional shrinkage ψ (%) ≥ 50, and a hardness HB ≤ 187.

Wide application fields:

SUS 347 is widely used in aviation, power generation, chemistry, petrochemicals, food, papermaking and other fields, and is also commonly used in the manufacture of equipment in high temperature environments and corrosive media.

In summary, SUS 347 stainless steel is widely used in many fields due to its excellent high temperature resistance, oxidation resistance, corrosion resistance, as well as good welding performance and heat treatment performance.

stainless steel processing

The manufacture of stainless steel involves a series of processes. First, the steel is melted, and then it is cast into solid form. After various forming steps, the steel is heat treated and then cleaned and polished to give it the desired finish. Next, it is packaged and sent to manufacturers, who weld and join the steel to produce the desired shapes.

Melting and Casting

The raw materials that constitute a stainless steel item are placed together and melted in a giant electric furnace. Intense heat is applied rigorously for a period of 8 to 12 hours during this step. Once the melting is complete, the molten steel is cast into desired semi-finished forms. Some of the most common forms or shapes include slabs, blooms (rectangular shapes), billets (these could either be round or square), rods, and tube rounds.

Forming

In the second stage, the semi-finished steel shapes undergo a series of forming operations. For instance, the stainless steel is hot rolled (heated and passed through enormous rolls). The blooms and billets mentioned above are converted to bar and wire. The slabs on the other hand are formed into plates, strips or sheets. It is very common to turn semi-finished steel shapes into bars, as it is the most versatile stainless steel form (it comes in all grades and sizes). You have round, square, octagonal, and hexagonal bars, each suitable for a different type of application.

Heat Treatment

The various stainless steel forms undergo a thorough annealing process during this step. Annealing is another name for heat treatment where the stainless steel is heated and cooled in a controlled environment. The purpose of this heat treatment is to relieve the pent-up stress inside the stainless steel and soften the material to make it more suitable for a wide variety of applications. The people in charge of carrying out the annealing process have to be very careful about the conditions as even the slightest of changes in the temperature, pressure, duration, or cooling rate could result in a faulty product.

Descaling

During the annealing process, a certain amount of scale appears on the surface of the stainless steel. This scale can be removed using a number of different processes that are collectively known as descaling. Pickling is one of the more common methods of carrying out the descaling process.

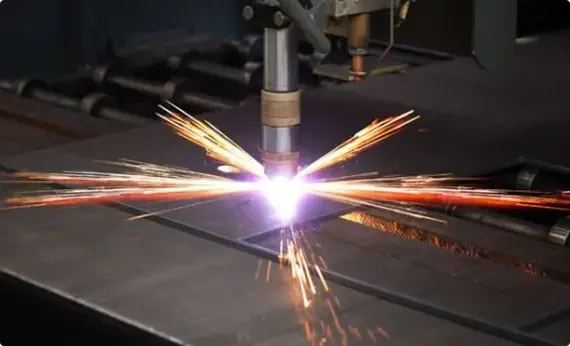

Cutting

The semi-finished, heat-treated, and descaled stainless steel forms are cut into specific shapes in this step. Mechanical cutting is performed with the aid of guillotine knives, blanking, nibbling, and high-speed blades.

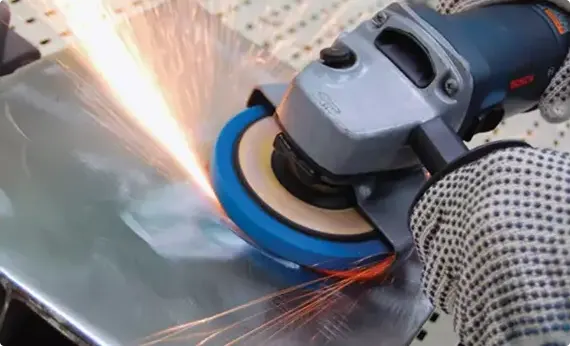

Finishing

Finishing is applied to help the stainless steel product achieve its signature aesthetically appealing appearance. Finishes are also needed to make the stainless steel product smooth and easier to clean, which is a top requirement in sanitary applications.